The heat-bonded and stitched filtering bags are the most suitable solution for a rapid and effective treatment of these liquids – even if they have high levels of viscosity and impurities – in industrial processes.

The filtering media is smooth on the inlet side and compact on the outlet side (due to a heat treatment). This ensures effective retention and accumulation of contaminants.

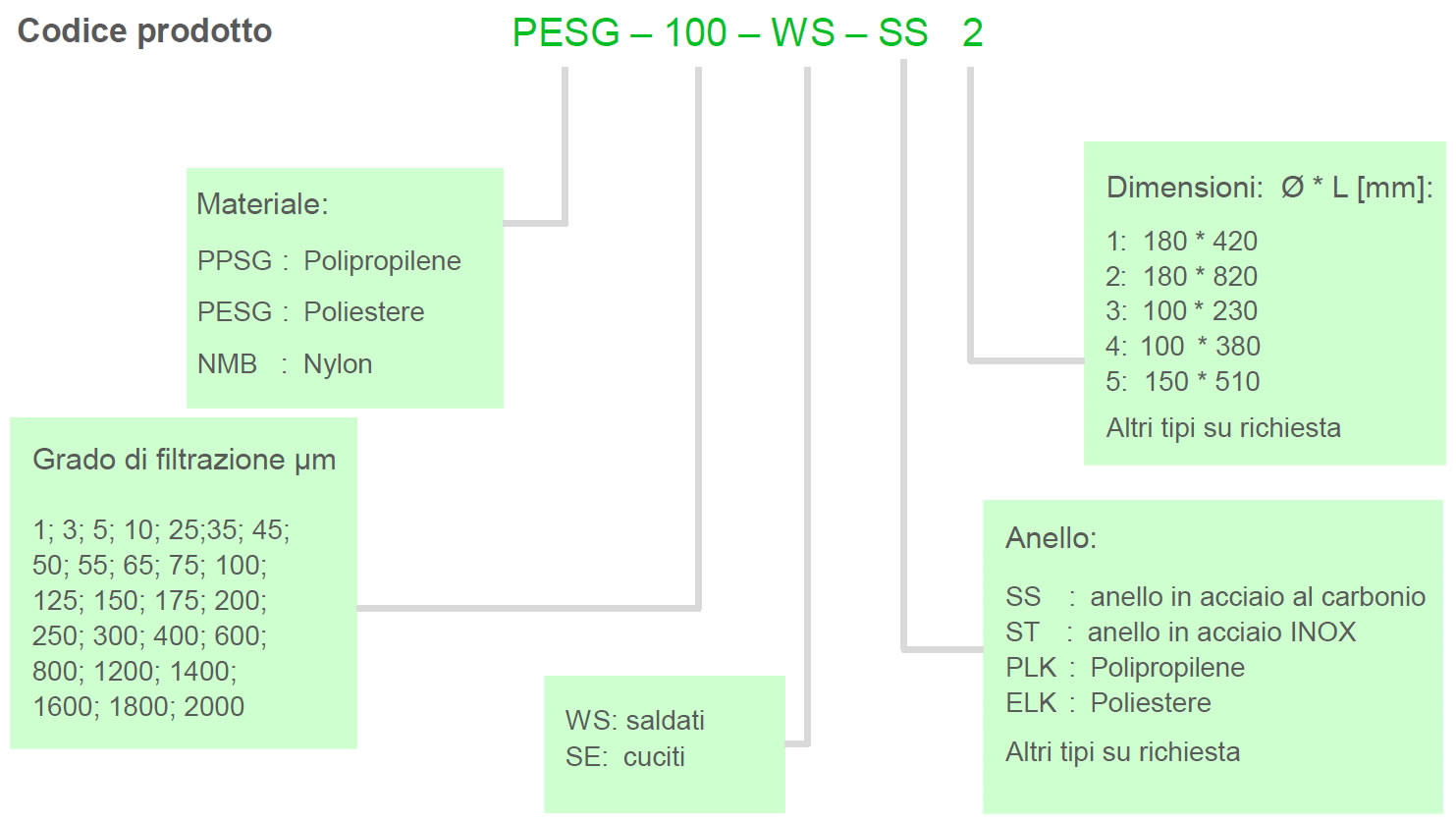

The filtering bags (liners, sleeves) are produced in various formats and dimensions, and in the open part have seal rings fitted with handles to facilitate their extraction from the containers.

They can be supplied with stitching or heat-bonded, in felt of various densities, and with seal rings in various materials: galvanised steel, 304 stainless-steel or polypropylene, which makes it possible to determine the capacity and quality of the filtering system. They are produced in various diameters and lengths. The materials used range from polyester to nylon for different filtering efficiencies, from 1 to 1000 microns. The seal ring can be made of metal or PVC.

Filtering Bags

Our Filtering Bags are used to process liquids for food use such as wine, beer and vegetable oils, as well as other types of liquids such as paints, petrol derivatives, adhesives and glues. They can be supplied HEAT-BONDED and STITCHED.

Request more information

Dati tecnici